Potato Tuber Cracking

(A2261 April, 2025)Tuber cracking is an external or surface disorder caused by environment, herbicides, or pests. Understanding sources of origin can help potato growers determine better farming practices to reduce this problem. Several photos showing tuber cracking are provided.

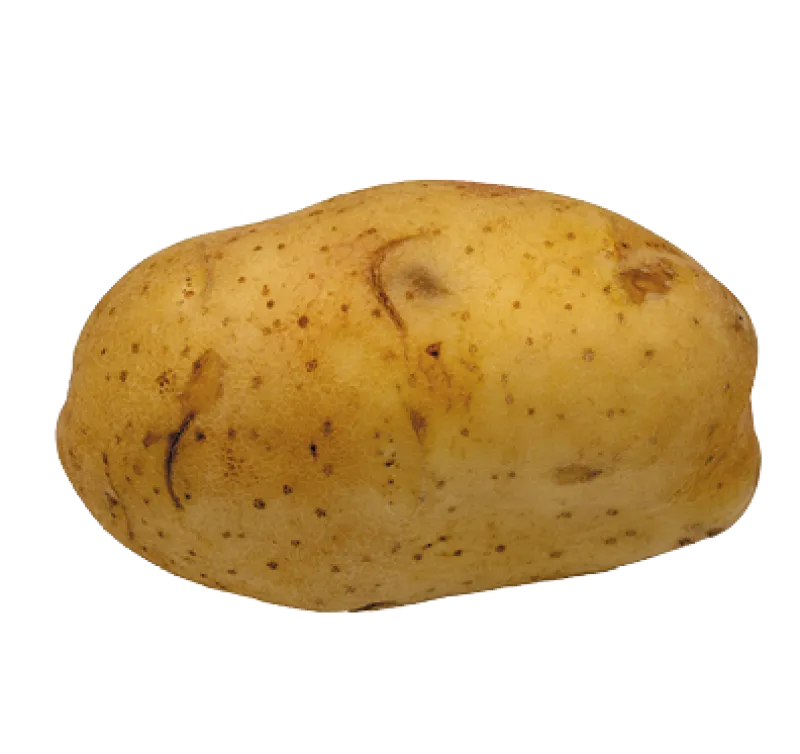

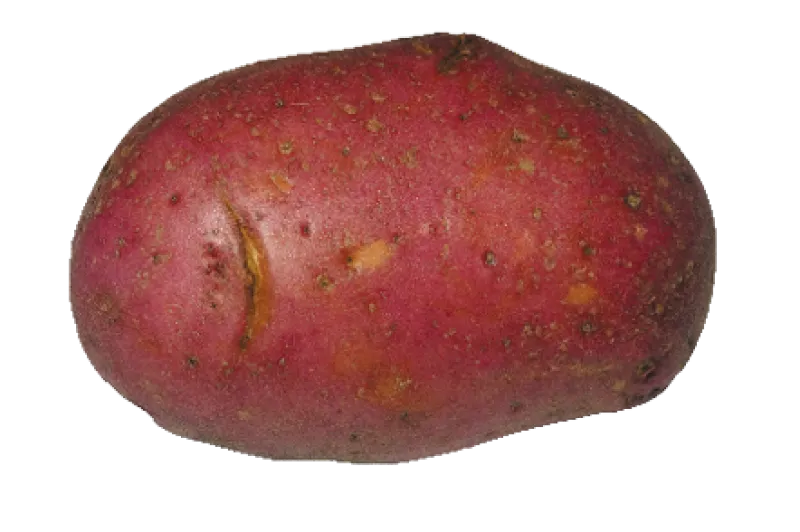

Tuber cracking is an external or surface disorder. It is noninfectious or often termed a physiological disorder, meaning it does not spread to other tubers. There are different types of tuber cracking that will be discussed in this article with a focus on growth cracks that are most common. Growth cracks (Figures 1a-c) develop during tuber development because of a physiological response to an environmental stress, herbicide injury or disease pressure. Air checks (Figure 2a-b), thumbnail cracks (Figures 3a-b) or shatter bruise (Figures 4a-b) are impact-related crackings that occur when tubers are harvested and handled. Tuber cracking in any form is not desirable and can result in quality loss and disease entry. The quantity and severity of tuber cracking will vary based on the cultivar, growing environment, disease pressure and handling.

Tuber growth cracks are caused when the internal core tissue grows faster than the surface tissue or periderm when tubers are enlarging. These cracks can vary tremendously in severity, with some tuber cracks being shallow and small and do not affect the grade while others are deep fissures that expand across the tuber and around the bud end and reduce the grade (Figures 5a-b). The severity of growth cracks can vary by cultivar. The number of tubers with cracking depends on the environmental, herbicides encountered, pathogens and other factors that disrupt tuber growth. Deep cracks can result in significant economic loss.

Growth cracks often occur when relatively poor growing conditions are rapidly followed by relatively good growing conditions, such as a period of low soil moisture followed by excessive irrigation or rainfall, causing rapid changes in tuber turgidity and growth rate. Other rapid changes in tuber growth reported to encourage growth cracks can come from poor nitrogen management during bulking, planting cultivars that tend to have larger-sized tubers or low-density planting. Tuber cracking most commonly occurs at the bud end of the tuber and stretches lengthwise (Figure 6), but cracking can happen anywhere on the tuber (Figure 7). Deeper growth cracks result from stress in early bulking, while shallow cracking happens later in bulking. As tubers continue to develop, growth cracks will suberize and heal.

Tuber growth may be disrupted by potato plant exposure to herbicides, resulting in growth cracks. Herbicide-induced cracking can be mild to severe (Figure 8a-c) and difficult to distinguish from growth cracks provoked by harsh environmental stress. Both systemic (translocating) and contact herbicides can cause growth cracks. Herbicides such as glyphosate, plant growth regulators or those that inhibit acetolactate synthase (ALS-inhibitors) commonly cause severe cracking when plants are exposed in early tuber bulking. Herbicide residues that remain in the soil and then are taken up by plant roots may result in cracked tubers (Figure 9). Exposure at late bulking may result in shallow cracking that may appear like skin checks or elephant hide (Figure 10) or no symptoms. The severity of cracking is affected by the interaction of cultivar, herbicide chemistry, herbicide rate, plant growth stage and environmental conditions. Testing tubers for herbicide residues at a reputable laboratory can help determine if herbicide injury has caused cracking.

Research has reported that a number of pathogens can cause tuber cracking, likely because they disrupt normal tuber development when plants are infected. Potato mop-top virus, potato virus A, potato virus V, potato virus Y, Potato spindle tuber viroid, Potato yellow dwarf virus and Rhizoctonia have been reported to cause tuber cracking (Figure 11). Bacterial ring rot, Clavibacter sepedonicus, can cause cracking of the skin, but when this is noted, typically wet breakdown is present as well (Figures 12a-b). Physiological disorders, such as pink eye (Periderm Disorder Syndrome), when severe, can cause shallow cracks in the tuber skin (Figure 13).

Determining the cause of growth cracks can be difficult because of the visual similarity of growth cracks caused by the environment, herbicides and pathogens. Examination of field patterns, foliar symptoms and laboratory testing of foliage and/or tubers can help determine if a disease, herbicide or environmental factor is the cause. Sometimes, there is nothing that can be done to prevent growth cracking because of the genetics of the cultivar and the environmental conditions the potato plants are exposed to during tuber development.

Strategies to reduce growth cracks include:

- Select cultivars that are less susceptible to cracking.

- Purchase certified seed that is free from disease and herbicide residues.

- Prepare soil to ensure good rooting for efficient water and nutrient uptake.

- Ensure uniform plant spacing and avoid low-density planting.

- Maintain adequate soil moisture and nutrition throughout the growing season.

- Prevent exposure to herbicides not labeled for potatoes.

Impact cracking of tubers can be the result of mild or severe impact when handling and storing cold, very turgid tubers. Thumbnail cracks (Figure 3) and air checks (Figure 2) are shallow, arch-shaped breaks in the skin. Sometimes, freshly dug tubers exposed to air or tubers in storage can develop thumbnail cracks. This cracking can also develop through poor handling, such as tubers knocking into tubers or tubers hitting unpadded areas when there is not adequate soil carried on the harvester or not having enough tubers on the conveying equipment or having long drops. Thumbnail cracks have been reported to occur when tubers have high hydration and temperatures are below 45 degrees Fahrenheit, or they can occur in storage or washing when the temperature rapidly changes. Thumbnail cracks often heal slowly, increasing tuber water loss and the potential for disease entry (Figure 14) during storage.

Strategies to reduce thumbnail cracks include:

- Avoid harvesting when tuber and air temperatures vary widely, especially when tubers are highly hydrated (turgid).

- Harvest and handle tubers with pulp temperatures between 45 to 65 degrees Fahrenheit.

- Reduce impact locations by keeping harvest and conveyors full, minimizing drops and padding equipment.

- Ensure proper wound healing in storage for 7 to 21 days, including providing high relative humidity (95%) and temperatures in the 55-degree Fahrenheit range, followed by a gradual drop (1 to 1.5 degrees Fahrenheit daily) to the desired storage temperature.

Shatter bruise (Figure 4), caused by impact to the tuber, causes splitting or cracking of the tuber. It most readily occurs when pulp temperatures are below 45 degrees Fahrenheit and tuber hydration levels are high. These cracks become more apparent when the tissue dehydrates and shrinks. Shatter bruise can cause cracking of the outer tuber surface and may extend deep into the tuber flesh. There are often multiple splits in various directions that result from this impact. Differences in genetics can affect potential for shatter bruise.

Strategies to reduce shatter bruise include:

- Keep pulp temperatures between 45 to 65 degrees Fahrenheit when harvesting.

- Maintain adequate soil moisture before harvest (available soil moisture should not be below 50% field capacity).

- Minimizing impact to tubers by reducing drops and adding padding to handling equipment.

NDSU Extension does not endorse commercial products or companies even though reference may be made to tradenames, trademarks or service names.

For more information on this and other topics, see www.ndsu.edu/extension